Air cleaning for industry without filters or chemicals

FLO-P Photolytic Oxidation System systems is designed for removal of grease & odors from exhaust air exceeding 45 dgc.

FLO-P systems is installed with automatic CIP cleaning systems. That means a minimum of maintenance of the daily basis as the unit cleans itself after use.

The contaminants in the air are oxidized or cold incinerated. Odors and organic particles contained in the air are reduced to an absolute minimum. The typical reduction in OU/m3 is about 90 – 98%.

The JIMCO industrial air purification systems are customized to client’s specific requirements based on air organic content, air temperatures, air flowrates, grease, and odor destruction requirements, etc.

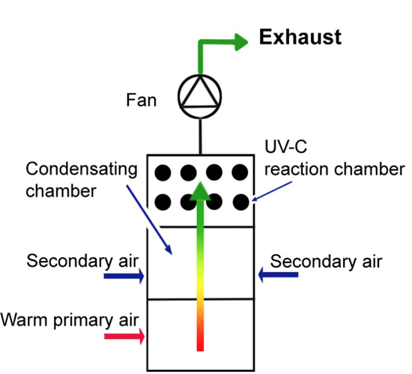

Step 1: Warm contaminated air (primary air) enters the lower part of the unit.

Step 2: The primary air passes through a maze filter resulting in the separation of large grease and water droplets.

Step 3: Primary air is cooled by mixing it with secondary air from the room (e.g. via a spot exhaust from a production line). The mixed air then passes over a bank of condensation blocks causing further grease/water separation from the air stream. This reduces power consumption during the photolytic oxidation process.

Step 4: The photolytic oxidation process is achieved using special low-pressure UV-C lamps that also generate a small quantity of ozone. Exposure to UV-C light breaks down organic compounds in the air and subsequent treatment with ozone completes the oxidation process.

The JIMCO industrial air cleaning system are based on the unique technology – photolytic oxidation.

The process of odour reduction and air treatment will be made by the application of the technology called Photolytic Oxidation Process, which uses a combination of ultraviolet radiation C and ozone.

Photolysis is a process in which UV-C radiation enables photon degradation of organic particles (e.g. fat and oil). Ozonolysis is an oxidation process in which organic particles are decomposed by ozone through a cold combustion. Ozone (produced by the lamps) is an unstable natural gas found in nature and helps to sterilize the earth’s surface.

The UV-C and Ozone technology used in the Jimco products have been developed, tested and documented in Germany and Denmark.

Both UV-C and Ozone is tested and documented to eliminate Coronaviruses like MERS and SARS, including SARS CoV2 – the source of Covid-19.

The calibrated amount of OZONE created by the specially designed and controlled UV-C lamps destructs the structure of and kills viruses, bacteria, fungi, and mold.

Application: Grease and Odor reduction from industrial exhaust systems, Air temperature above 45 dgc

Reaction chamber: Acid proof stainless steel (SUS 316)

UV-C Lamps: Jimco Photozone lamps™. The actual number of units and power required is designed according to the pollutant treated as well as volume of air.

Control system: Industrial PLC-controller, incl. modem and alarm signals.

Cleaning systems: The FLO-P systems is installed with automatic CIP That means a minimum of maintenance of the daily basis as the unit cleans itself after use. The CIP system is controlled by the PLC-controller with the required cleaning sequence.

FLO-K Photolytic Oxidation systems is designed for removal of odors from exhaust less than 45 dgc.

The FLO-K system does not require a secondary air to cool the primary air to be treated.

The contaminants in the air are oxidized or cold incinerated. Odors and organic particles contained in the air are reduced to an absolute minimum. The typical reduction in OU/m3 is about 90 – 98%.

The JIMCO industrial air purification systems are customized to client’s specific requirements based on air organic content, air temperatures, air flowrates, grease, and odor destruction requirements, etc