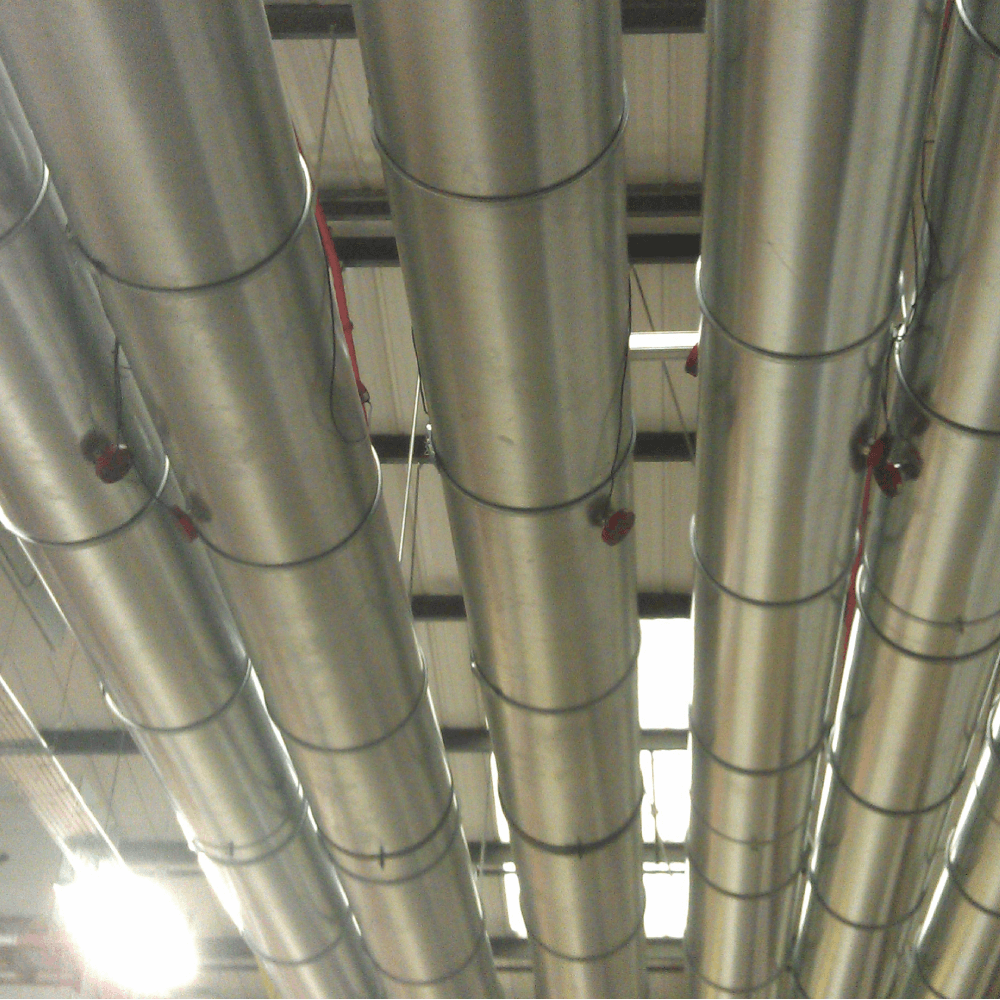

Using infrared detectors, the Spark Detection and Extinguishing System, searches for elevated temperature particles. The greatest sensitivity occurs when detectors are employed in a dark area, which is easily achieved in closed ductwork. However, optional ‘daylight detectors’ are available. When a spark is detected, the Spark Detection and Extinguishing System provides many options to manage the ignition risk:

1. Active extingushing water spray nozzle placed downstream of the detection point.

2. Activate automated shut-down of the process to end the feed of combustible material.

3. Provide a signal to activate other control devices’ shut-off valves.

The Spark Detection and Extinguishing System operates in a continuous automatic mode with all of its critical circuits monitored to raise an immediate alarm in case of malfunction.

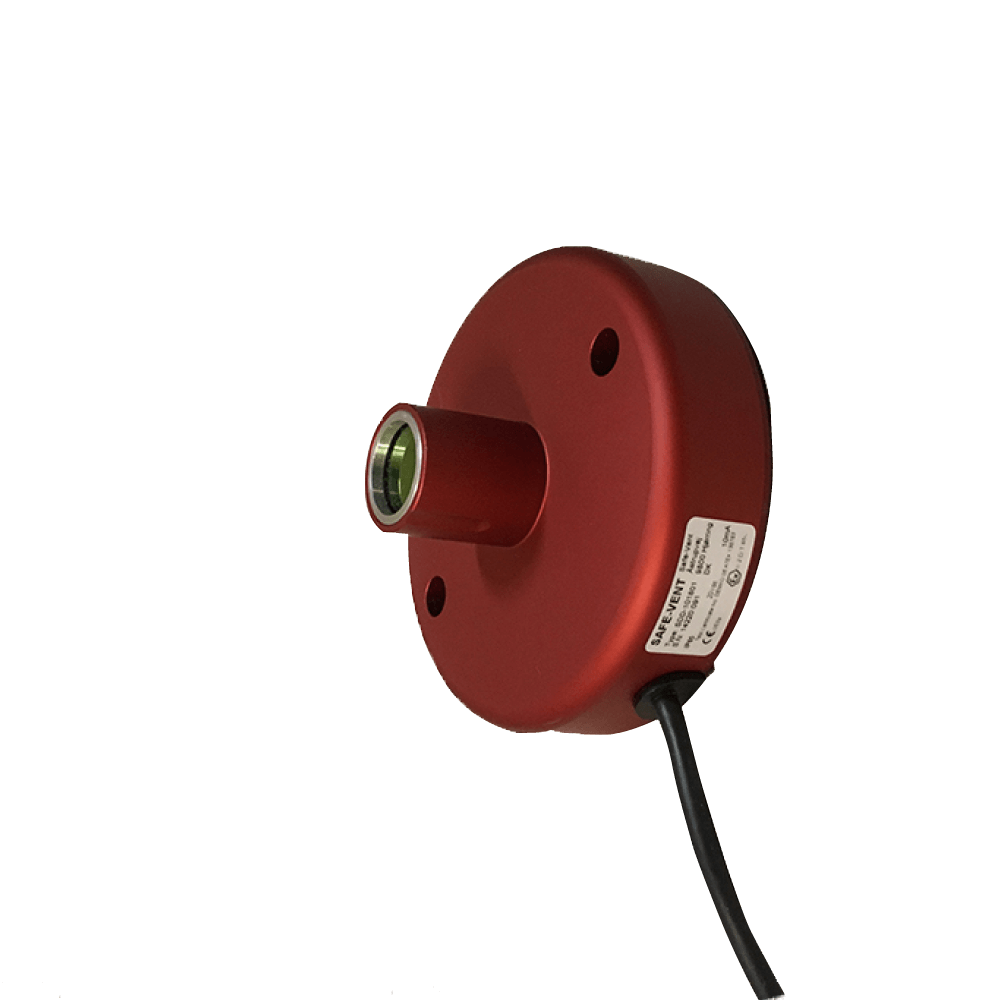

The Spark Detection and Extinguishing System uses highly accurate type SDN or SDD spark detector to sense sparks, embras and flames.

An electrical signal generated by the sensor activates control circuits, which will start the selected countermeasures to quickly and efficiently eliminate the potentially dangerous particles, thereby preventing explosions and fires.

Production continues undisrupted while our Spark Detection and Extinguishing System operates

The SDN and SDD detectors are conveniently installed from outside the pipe or duct using an adaptor. The adaptor contains a sapphire glass window through which the detector observes the process. An optional air purged adaptor is recommended for applications with high dust loading.

The Spark Detection Type SDN is designed for use in total darkness. The highly sensitive detector sense infrared light and is able to peer through dense phase material. The operating temperature range is from -40°C (-104°F) +70°C (+158°F). The temperature range can be expanded by use of optional flexible glass fiber cables, 1-or-2 meters long (3-or-6 feet).

The Spark Detection Type SDD is designed for use in area that are lit by daylight or electric lights. It has the same robust design, as the SDN, making it able to withstand temparetures ranging from -40°C (-104°F) +70°C (+158°F). The temperature range can be expanded by use of optional flexible glass fiber cables, 1-or-2 meters long (3-or-6 feet).

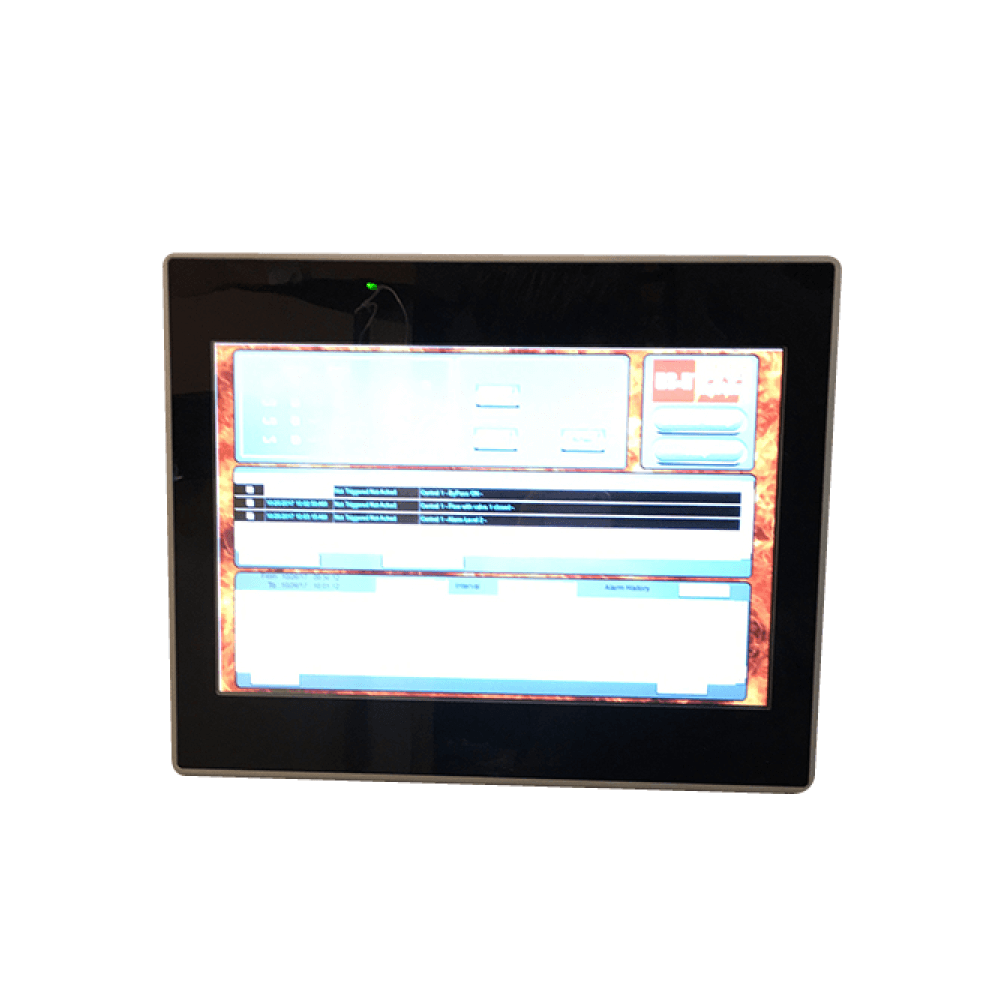

The DC1 performs as a decentralized control unit designed for field installation in the hazardous dust environment. Each DC1 can control and monitor up to 4 spark detectors and 2 automatic extinguishing modules. The DC1 can monitor 1 installation or 2 independent installations and provides a 2-stage alarm; stage 1 at each system actuation – stage 2 at a user-set threshold.

If several systems are applied in the same process, the individual DC1 Control Units can be connected to one Central Monitor via a single wire data connection (CAN-bus). Such a system can incorporate up to 34 DC1 units.

The Control Panel provide a centralized overview of all system components. Touch screen uses a simple interface with self-explanatory menu items. Control panels are available in 2 sizes as well as monochrome or color. The optional control panel is used to monitor up to 34-independent Spark Detection and Extinguishing Systems.

The Automatic Extinguisher SA1 – 4 is made of 5 parts: a nozzle, an electromagnet, a solenoid valve with high-speed opening technology, a stop valve and a filter. The Extinguisher’s operating pressure is between 5 and 10 bar. This secures an effective water barrier for extinguishing the sparks. The Auto Extinguisher is manufactured to cover all pipe or duct dimensions and shapes. An easy-to-mount adaptor is included.

The Spark Detection and Extinguishing System is fully automatic.

The DC1 Control Unit automatically tests: - Spark Detector function - Battery voltage of integral back-up batteries - Connection of optional water spray nozzle system - Operation of optional trace heating (Frost protection for water spray systems) In addition, owner/operater personnel can conduct a manual test to verify system status at any time.

Via a touch of the DC1 Control Unit keypad you can perform a manual test which makes the same checks as the automatic test routine. The manual check additionally verifies the presence of extinguishing water when spray nozzles are triggered by the system. Manual testing is used upon start-up of the system to verify its proper function and for training of owner / operator personnel.

Alerts are provided by means of a local alarm (flashing lights and horn) whenever sparks is detected and extinguished. Alerts are cancelled manually at the DC1 Control Unit. The spark detection and extinguishing system operates with three alarm stages, that can be customized to your unique processes.